مقالات و نوشتار های تحلیلی

70 مطالعه موردی از پروژه های BIM مبنا در بریتانیا

CASE STUDY: UTC WOLVERHAMPTON

A BIM EXEMPLAR AT TRAINING ESTABLISHMENT

20 JUNE 2016 | BY TOM RAVENSCROFT

- Client: Education Funding Agency

- Lead Contractor: Thomas Vale, M&E contractor LJJ

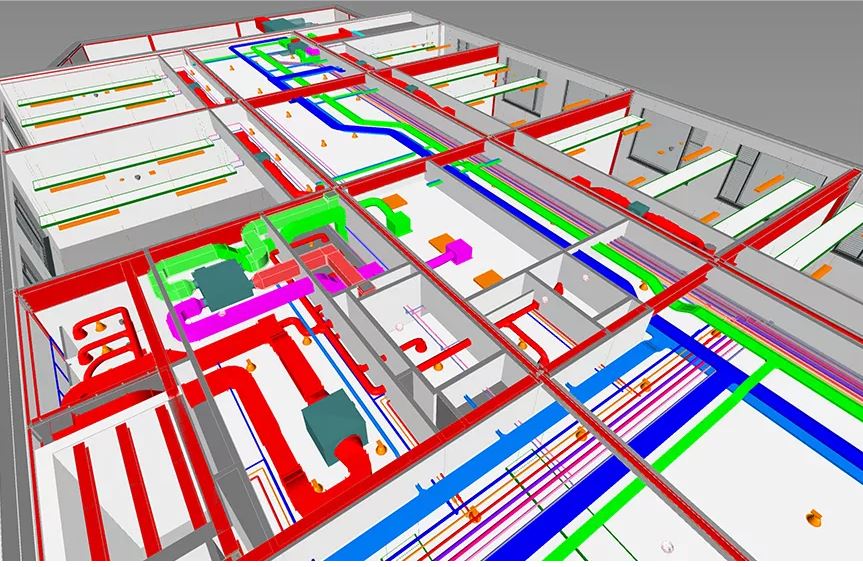

The £10m University Technical College (UTC) in Wolverhampton, designed by Associate Architects, is being built in a former brewery to provide advanced level training in construction and the application of information technology in the built environment. As such it was determined that the project would be built as an exemplar with BIM integral to its design and construction.

Chris Lavin, pre-construction manager at M&E contractor LJJ, explains: “The decision to use BIM was client driven. As the college is teaching a construction-based curriculum the client wanted to use the model as a teaching aid upon completion to allow the students to access it and navigate it and has been very keen to incorporate construction best practice in every element of the scheme.”

The project is financed by the Education Funding Agency (EFA), so it falls under the requirement for centrally procured publically funded projects to be delivered in BIM Level 2 and it also meant that the delivery team had to achieve an ambitious scheme on a restricted budget.

“Part of the goal of delivering the scheme in BIM is to maximise cost efficiencies both during the build and throughout the lifecycle of the college, and the BIM models will provide invaluable operational and maintenance data,” says Lavin. “They will also support adaptability which is important in any education environment and particularly so in a technically-driven college like Wolverhampton UTC.”

Although the building fabric and steelwork were modelled in BIM, due to budget constraints BIM was only utilised on certain elements of the M&E design, such as the plant room areas, where coordination between services is critical, and pinch points where the services pass through heavily congested areas.

Only the kitchen contractor and the fixed furniture contractors did not use BIM, explains Lavin: “All other members of the team were fully engaged with the BIM process, including both consultants and contractors. Importantly, the client was also very engaged with BIM and was actively involved in the collaborative process.”

As the project is still on site its hard to judge whether money has been saved, adds Lavin, but he does believe from an M&E point of view BIM has improved clash detection and helped to prevent any unforeseen delays or additional works on site, which reduces labour requirements and makes it easier to remain on schedule.

Overall BIM has achieved positive outcomes in terms of improved efficiency and interdisciplinary communication and according to Lavin it has also thrown up some valuable lessons, such as the necessity to get essential elements signed off early in the process.

“The efficiency of a BIM project relies on early engagement and accurate input of all building elements into the models and that approach needs to be built into working cultures,” he says. “There has to be a transition between the less efficient but more flexible processes of working in 2D towards the more rigid but efficient processes of working in BIM.”

The only time the software was not up to the job was when dealing with the existing listed elements of the former brewery. According to Lavin, the technology used to survey an existing structure and input it into a BIM model does not appear to be that advanced.

“The old goods lift shaft in the former brewery building forms the main ducting route, which then runs across a glass link that has been designed to connect the new building to the main elevation of the old brewery”, he says.

“While the integration of old and new helped to inform the strategy for the ventilation system layout, some of the obvious ducting routes were not available, as it was not possible to make openings in walls for structural or heritage reasons.

“In the end, the mechanical team had to take a creative approach to designing the ventilation system and due to time constraints and the inflexibility of the technology, the M&E design for the existing building has been carried out in 2D with the new build in BIM.”

از لینک زیر می توانید به 70 نمونه پروژه BIM مبنا در بریتانیا دستیابی پیدا نمائید .

http://www.bimplus.co.uk/projects/dynamo-pow8ers-soft4ware-scri4pting/

راهکارهای هوشمند BIM ایران

WWW.iiBIMsolutions.ir

منبع :

سایت bimplus.co.uk

![]() استفاده از مطالب، فقط با ذکر منبع مجاز است. حق پیگرد بر اساس قانون حمایت از حقوق مؤلفان و مصنفان، محفوظ میباشد.

استفاده از مطالب، فقط با ذکر منبع مجاز است. حق پیگرد بر اساس قانون حمایت از حقوق مؤلفان و مصنفان، محفوظ میباشد.